Hotmelt Strap: The Smart Choice for Secure and Efficient Load Securing

In the modern logistics and packaging industry, the need for safe, reliable, and efficient load securing solutions is greater than ever. Whether transporting recyclable materials, bundling heavy construction goods, or exporting merchandise across long distances, one essential product has been gaining widespread popularity across industries: the hotmelt strap. This type of strapping combines strength, flexibility, and safety in one product, making it a preferred alternative to steel strapping and traditional plastic bands.

What is Hotmelt Strap?

A hotmelt strap is a type of non-woven polyester strapping made by bonding high-tensile polyester filaments together using heat-activated adhesive. Unlike woven straps, hotmelt straps are not interlaced but are fused into a flat, cohesive structure. This unique manufacturing process results in a strap with consistent width, high tear resistance, and excellent elongation properties.

These straps are often referred to as bonded polyester straps or glued polyester straps, and they are available in a variety of widths, thicknesses, and breaking strengths depending on the application.

Key Features and Advantages

-High Tensile Strength

One of the main reasons hotmelt straps are widely used is their exceptional tensile strength. They can secure heavy or irregularly shaped loads without snapping or stretching excessively. This strength is achieved through the combination of industrial-grade polyester yarns and the uniform bonding process.

-Shock Absorption and Elasticity

Hotmelt straps have a moderate level of elasticity, allowing them to absorb shocks and maintain tension even when the load shifts during transit. This feature is particularly valuable in long-distance shipping, where goods may be subjected to vibrations, sudden movements, or temperature fluctuations.

-Safety in Handling

Unlike steel straps, hotmelt straps do not have sharp edges, do not rust, and do not rebound dangerously when cut. This makes them much safer to use, reducing the risk of worker injuries and product damage. Many companies choose hotmelt strap specifically to improve safety protocols in packaging and logistics departments.

-Resistance to Weather and Chemicals

Hotmelt straps are resistant to moisture, ultraviolet radiation, and many chemicals. These properties make them suitable for both indoor and outdoor use. Whether in a humid warehouse, under direct sunlight, or in cold shipping containers, the strap maintains its integrity.

-Cost Efficiency

Compared to steel strapping, hotmelt strapping is significantly more affordable—not only in terms of material cost but also handling and equipment. The lighter weight reduces shipping costs, and it can be applied without the need for expensive tensioners or sealers. In many cases, simple manual tools and metal buckles are sufficient.

Applications Across Industries

Hotmelt straps are used in a wide variety of sectors thanks to their versatility and reliability.

-Recycling Industry

In the recycling sector, hotmelt straps are used to bundle compressed bales of paper, cardboard, plastic, and textiles. They are compatible with manual, semi-automatic, and fully automatic balers, making them an essential material in waste management and recycling facilities.

-Construction Materials

The construction industry often requires the bundling and securing of heavy, bulky items such as bricks, tiles, wood panels, metal rods, and piping. Hotmelt strap is ideal for these purposes due to its strength and shock-absorbing capabilities.

-Export and Pallet Securing

When goods are exported via land, sea, or air freight, securing them to pallets is critical. Hotmelt straps provide stable and safe bundling for cartons, crates, and other export packaging. Their resistance to environmental factors makes them a reliable solution for international shipping.

-Logistics and Warehousing

In warehouse operations, hotmelt straps are used to bundle products for easier handling, storage, and movement. They can be used with mobile strapping tools or hand tensioners, offering flexibility for different packaging needs.

-Agriculture and Forestry

Farmers and forestry businesses use hotmelt straps to secure agricultural products, hay bales, fertilizers, logs, and machinery parts. The strap’s flexibility makes it suitable for irregularly shaped goods and rough surfaces.

Comparison with Other Strapping Materials

When considering different strapping solutions, it is important to compare hotmelt strap with alternatives such as steel strapping, woven polyester strap, and polypropylene (PP) strap.

Compared to steel strapping, hotmelt strap is safer, lighter, corrosion-free, and easier to apply. While steel has higher tensile strength, hotmelt strap performs better in terms of flexibility and resistance to impact.

Compared to woven polyester strapping, hotmelt straps are often more cost-effective due to a simpler manufacturing process. Woven straps may have higher flexibility, but hotmelt straps offer a smoother surface and more uniform strength.

Compared to PP strap, hotmelt strap is significantly stronger and more durable. PP straps may be sufficient for lightweight or temporary applications, but hotmelt strap is the better choice for medium to heavy-duty load securing.

Environmental and Sustainability Considerations

Sustainability is an increasingly important factor for businesses. Hotmelt straps support environmental goals in several ways. Polyester, the main material used in hotmelt straps, is recyclable. Moreover, using lightweight and recyclable strapping helps reduce carbon emissions during transportation and supports a circular economy approach.

By replacing steel strapping with hotmelt alternatives, companies can also reduce energy use in production, as well as occupational hazards, contributing to cleaner and safer workplaces.

How to Use Hotmelt Strap Effectively

To get the best results from hotmelt strapping, users should select the appropriate strap width and strength based on their load requirements. The most common widths are 13mm, 16mm, and 19mm, but wider options such as 25mm are also available for particularly heavy loads.

Hotmelt straps can be applied using:

- Manual tensioners and metal buckles

- Pneumatic or battery-powered strapping tools

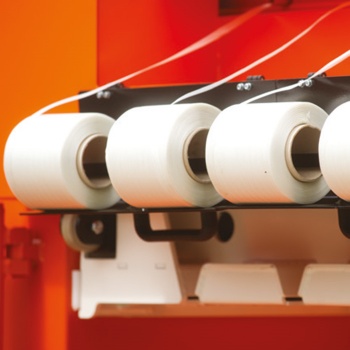

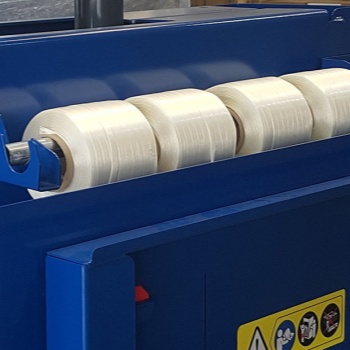

- Integration with baling machines for automated operations

It is also important to ensure that the strapping is stored properly, away from excessive moisture and sunlight, to preserve its properties.

Choosing a Reliable Supplier

When sourcing hotmelt strapping, selecting a reputable and experienced manufacturer is essential. Reliable suppliers ensure consistent product quality, offer technical support, and provide fast delivery. Ideally, the supplier should also offer matching buckles and tools to simplify procurement and improve efficiency.

Final Thoughts

Hotmelt strap represents an evolution in load securing technology. Combining strength, safety, cost efficiency, and environmental advantages, it is an ideal solution for companies seeking modern and reliable packaging methods. Whether you are in recycling, manufacturing, export logistics, or agriculture, adopting hotmelt strapping can improve safety, reduce costs, and enhance operational performance.

As global supply chains become more demanding, products like hotmelt straps are no longer optional—they are essential tools for ensuring goods arrive safely and efficiently from point A to point B.