Top 5 Advantages of Using Cord Lashing Straps in Industrial Shipping

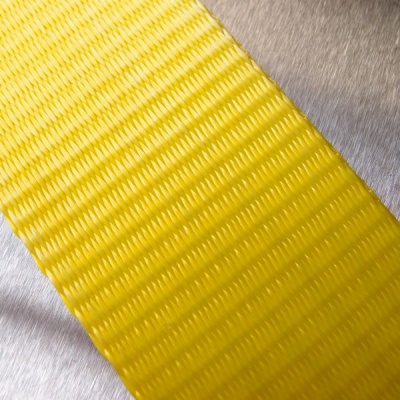

In the world of industrial logistics, where cargo safety, efficiency, and cost-effectiveness are key, choosing the right strapping solution is crucial. Among the various types of strapping materials available on the market, Cord Lashing Straps have gained widespread recognition for their durability, performance, and adaptability. These polyester-based straps are designed to secure heavy-duty cargo during transportation, whether it’s by land, sea, or air.

Compared to traditional strapping methods like steel or polypropylene strapping, Cord Lashing Straps offer a wide range of advantages that make them an ideal choice for industrial shipping. In this article, we explore the top five benefits of using Cord Lashing Straps in logistics and transport applications.

1. High Tensile Strength and Load Stability

One of the most important features of Cord Lashing Straps is their exceptional tensile strength. These straps are manufactured using high tenacity polyester fibers, which provide excellent resistance to tension and shock. This makes them especially suitable for securing heavy loads such as machinery, construction materials, timber, or palletized goods.

Cord Lashing Straps are engineered to maintain consistent tension throughout the journey, ensuring that the cargo remains securely fastened even under conditions of vibration or shifting. Unlike steel straps, which can lose tension due to elongation or deformation, Cord Lashing Straps retain their grip, reducing the risk of load movement that can lead to product damage or accidents during transportation.

Additionally, Cord Lashing Straps are available in various breaking strengths, ranging from 1000 daN up to 7500 daN or more, depending on the specific application. This range allows users to select the appropriate strength based on the weight and nature of the cargo.

2. Safety for Users and Cargo

Safety is a top priority in any industrial environment. Cord Lashing Straps offer a distinct advantage over steel strapping when it comes to worker and cargo safety. Steel straps, while strong, can pose significant risks due to their sharp edges. Improper handling or cutting can result in serious injuries, including cuts, punctures, or eye injuries.

Cord Lashing Straps, on the other hand, are lightweight and soft to the touch, with no sharp edges. This makes them much safer for workers during application and removal. They can be easily cut with standard tools, without causing recoil or flying fragments.

Furthermore, the flexibility of Cord Lashing Straps helps reduce damage to cargo. The straps conform to the shape of the goods and distribute the pressure evenly, preventing abrasions or dents. For delicate or high-value cargo, this added protection is essential to maintain the quality and integrity of the products during shipment.

3. Resistance to Environmental Conditions

Industrial shipping often involves exposure to harsh environmental conditions, especially for goods transported across long distances by sea or in open-air settings. Cord Lashing Straps are designed to withstand a variety of environmental factors, including moisture, UV rays, temperature changes, and chemicals.

Unlike steel straps, which are prone to rust and corrosion when exposed to water or humid environments, Cord Lashing Straps are rust-proof and non-corrosive. This makes them ideal for maritime shipping, where saltwater and humidity are constant challenges.

The polyester fibers used in Cord Lashing Straps are also UV-resistant, meaning they can retain their strength and color even after prolonged exposure to sunlight. In addition, they are resistant to many chemicals and oils commonly encountered in industrial settings. These qualities contribute to a longer lifespan and more consistent performance, reducing the frequency of strap replacement and overall logistics costs.

4. Easy Handling and Efficient Application

Efficiency in packaging and securing cargo can significantly affect operational timelines and labor costs. Cord Lashing Straps are designed for fast and easy application, making them a preferred choice for logistics teams.

The lightweight nature of these straps makes them easier to carry and maneuver compared to steel straps or bulky ratchet systems. They can be applied using manual tensioners and buckles, without the need for heavy-duty tools or machinery. This makes the process of securing cargo faster and more flexible, especially in remote or fast-paced environments.

Cord Lashing Straps can also be used in a variety of configurations, including vertical, horizontal, crosswise, or looped lashing patterns. This versatility allows for customized solutions tailored to different cargo shapes and sizes. Whether you are securing goods on a flatbed truck or inside a shipping container, Cord Lashing Straps provide a reliable and user-friendly option.

5. Cost-Effective and Eco-Friendly Solution

Lastly, Cord Lashing Straps offer a cost-effective alternative to traditional strapping materials. Although their initial cost may be comparable or slightly higher than polypropylene straps, their superior strength, reusability, and lower risk of damage lead to significant cost savings in the long run.

The reduced risk of cargo damage and workplace injuries translates to fewer insurance claims and medical costs. In addition, their durability means that fewer straps are required per shipment, and in some cases, they can be reused depending on the condition and application.

Many Cord Lashing Straps are also recyclable and manufactured with environmentally friendly materials. As industries across the globe move toward sustainable practices, using recyclable packaging materials like Cord Lashing Straps contributes positively to a company’s environmental footprint.

Conclusion

The demand for safe, strong, and reliable strapping solutions continues to grow across industrial sectors, from manufacturing to logistics, construction, and warehousing. Cord Lashing Straps meet these demands by offering a unique combination of high tensile strength, user safety, environmental resistance, ease of application, and cost efficiency.

For companies looking to improve their cargo securing systems and minimize risks during transportation, Cord Lashing Straps represent a modern and effective solution. Investing in high-quality Cord Lashing Straps not only ensures the safety of goods in transit but also contributes to smoother operations, greater customer satisfaction, and better long-term value.

If you're searching for a dependable strapping option for your industrial shipping needs, Cord Lashing Straps are certainly worth considering.